Industry

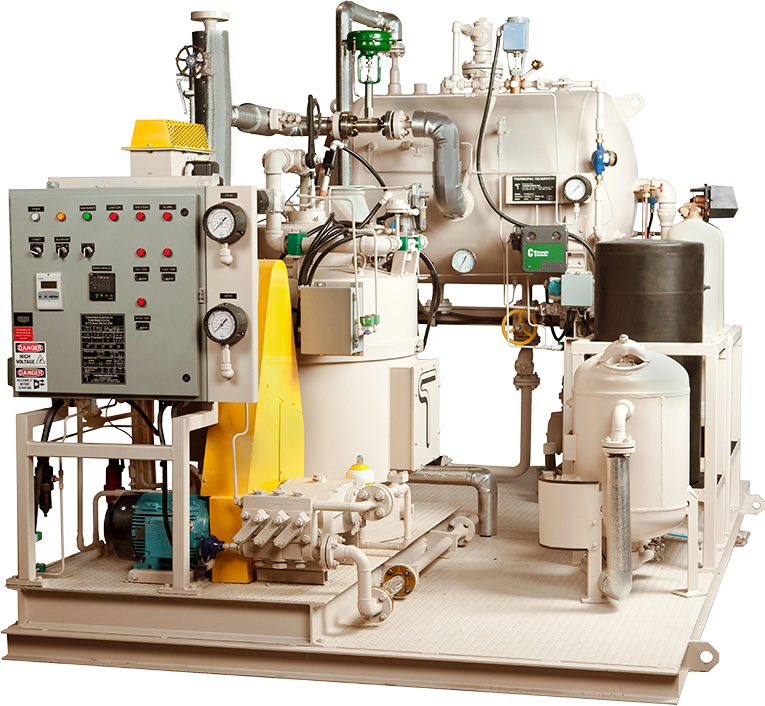

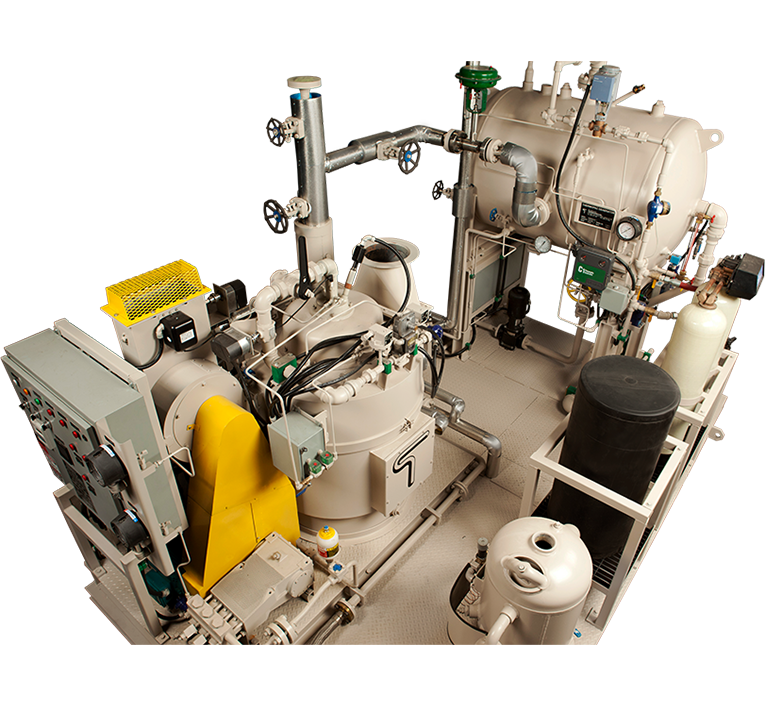

High Pressure Steam Boilers for the Valve Testing Market

- Consistent delivery of high pressure dry steam (1750psi - 2850psi)

- Quick steaming; cold to full output in less than 5 minutes

- Compact Footprint for tight installations. Containerized and skid solutions available.

- Full modulating