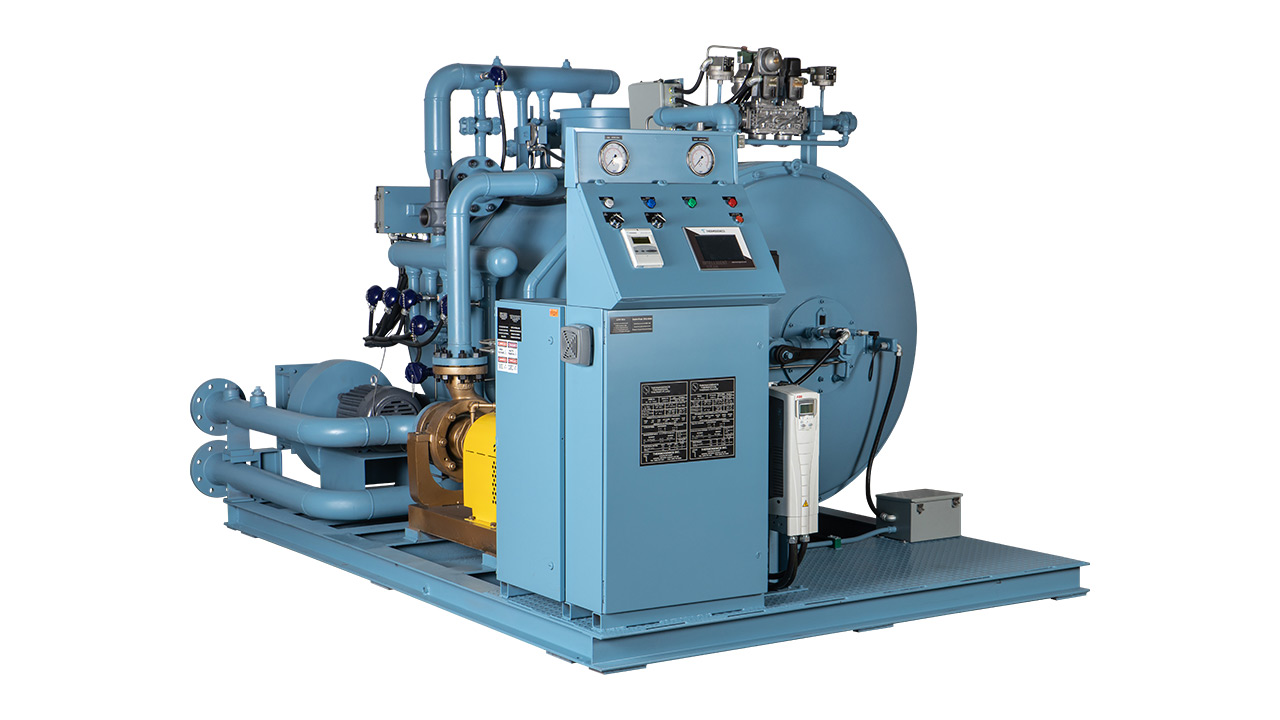

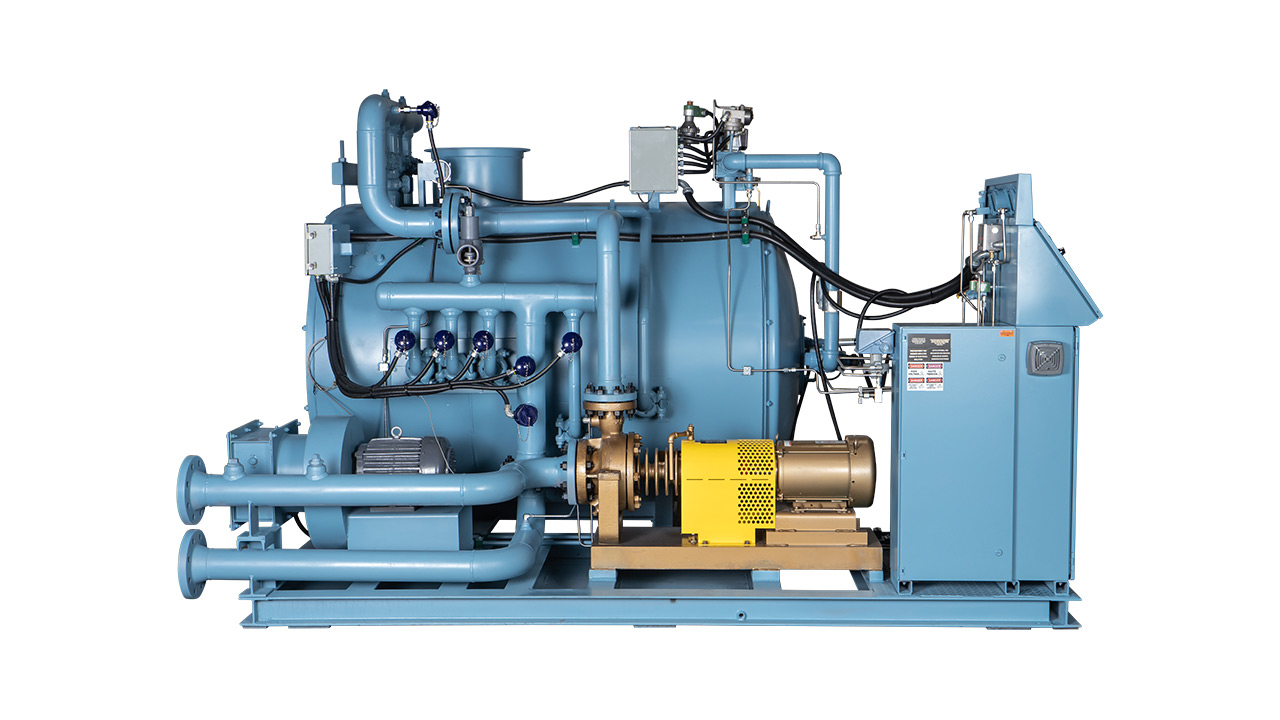

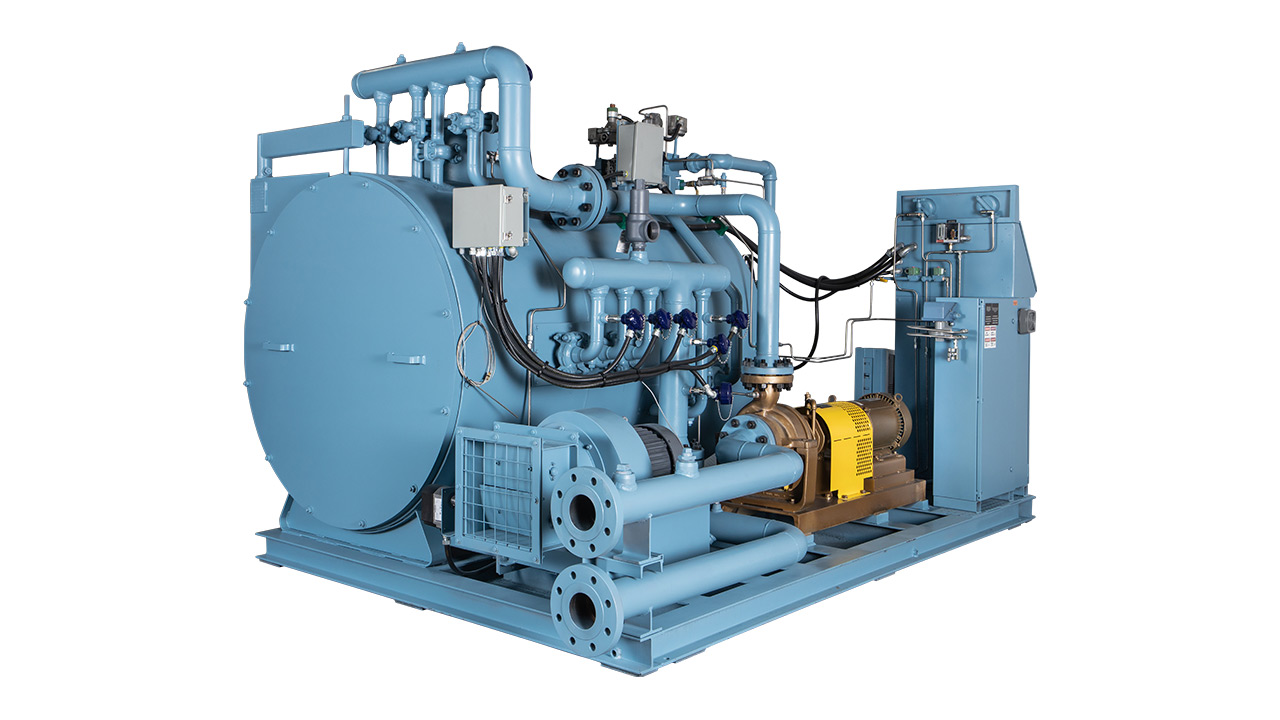

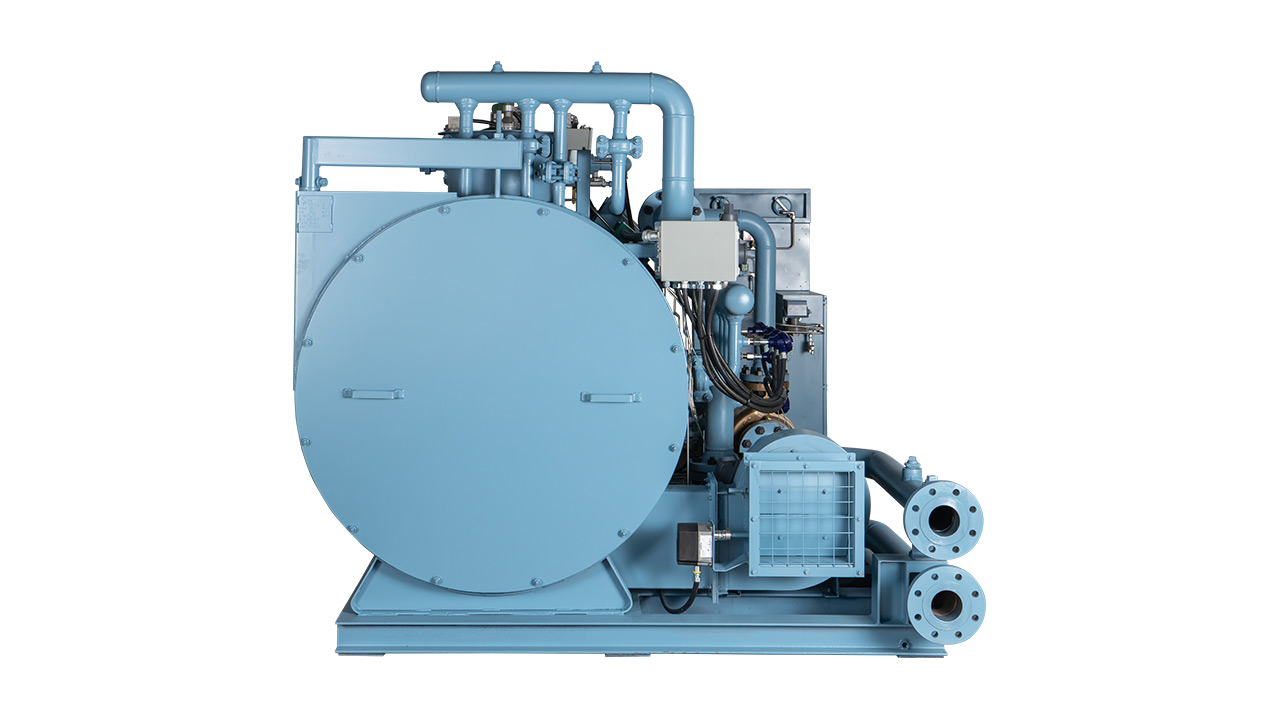

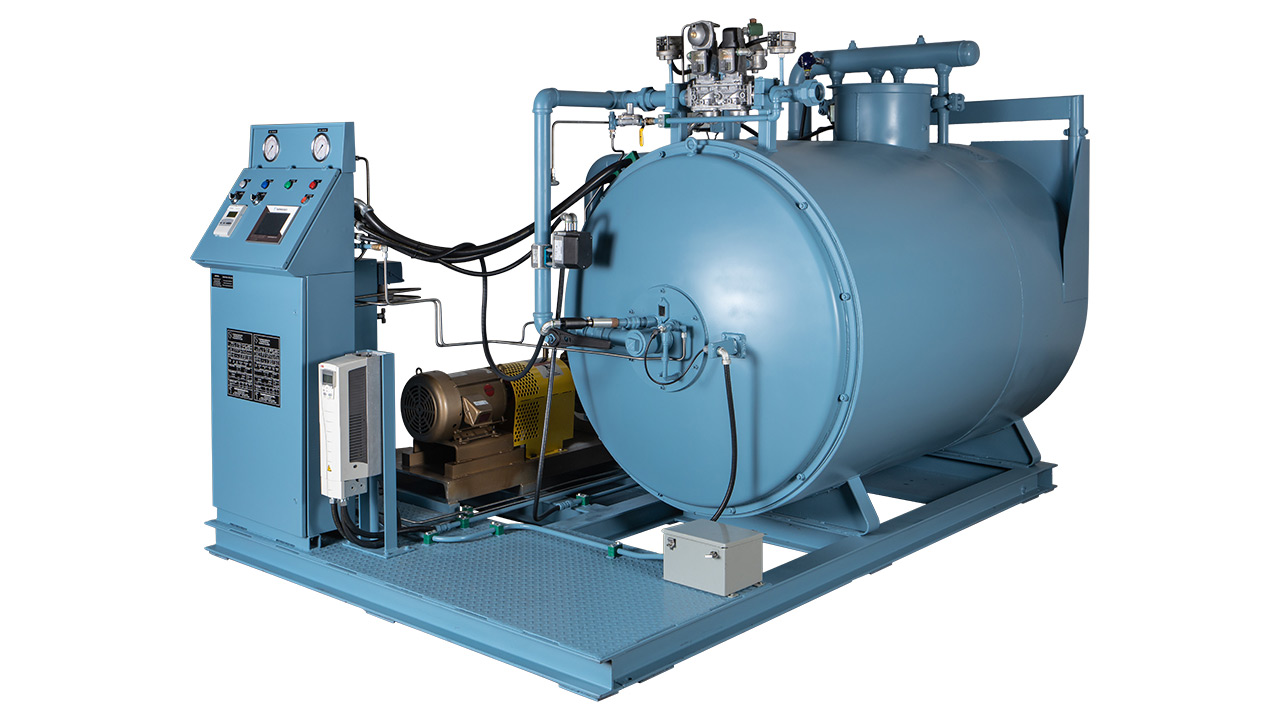

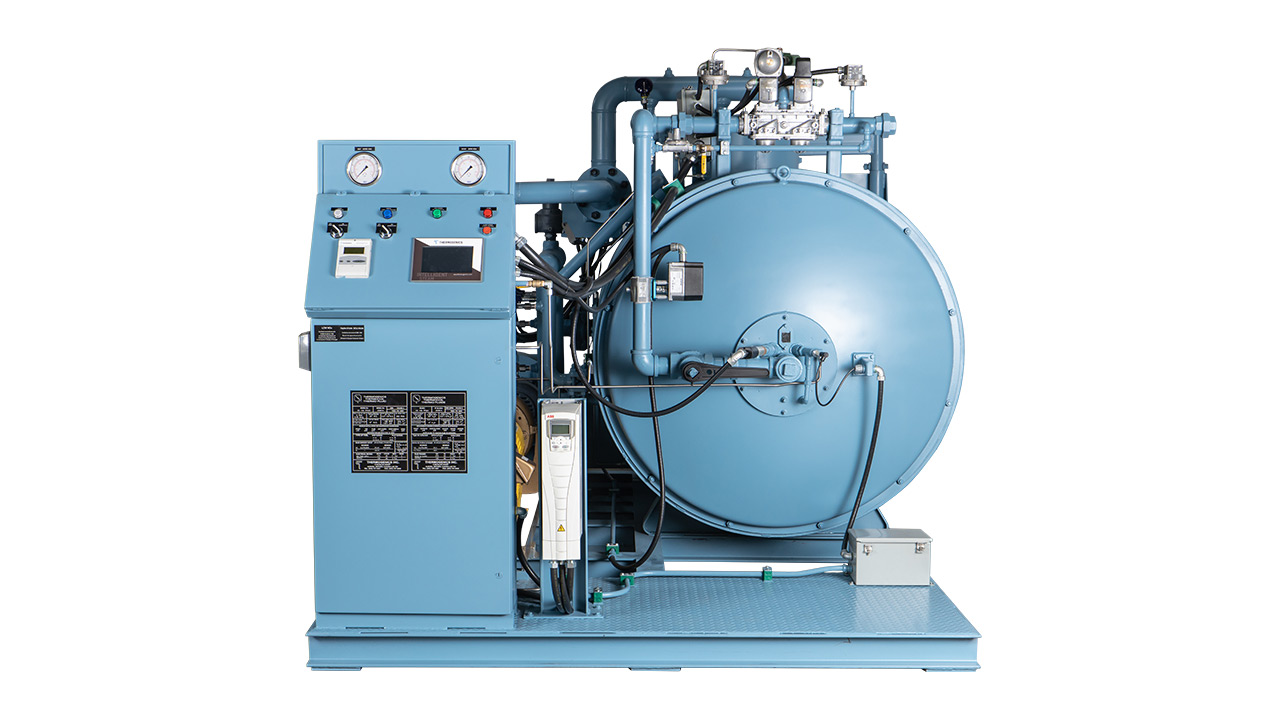

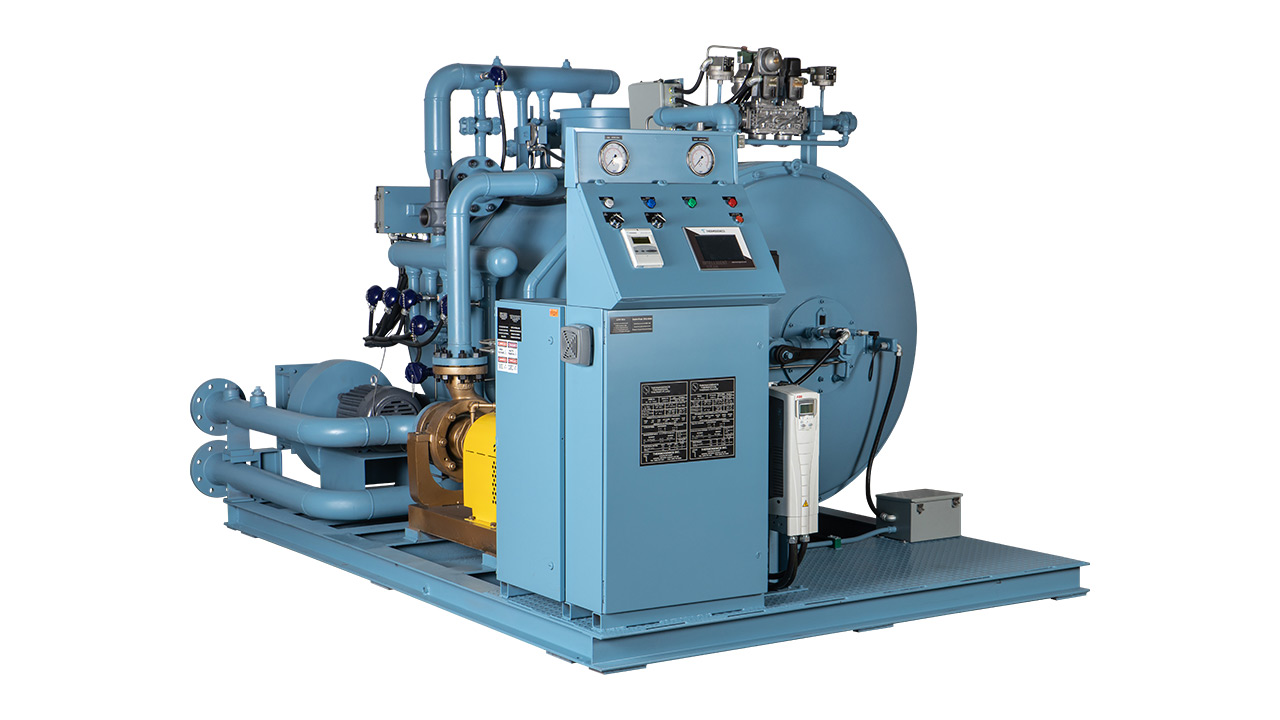

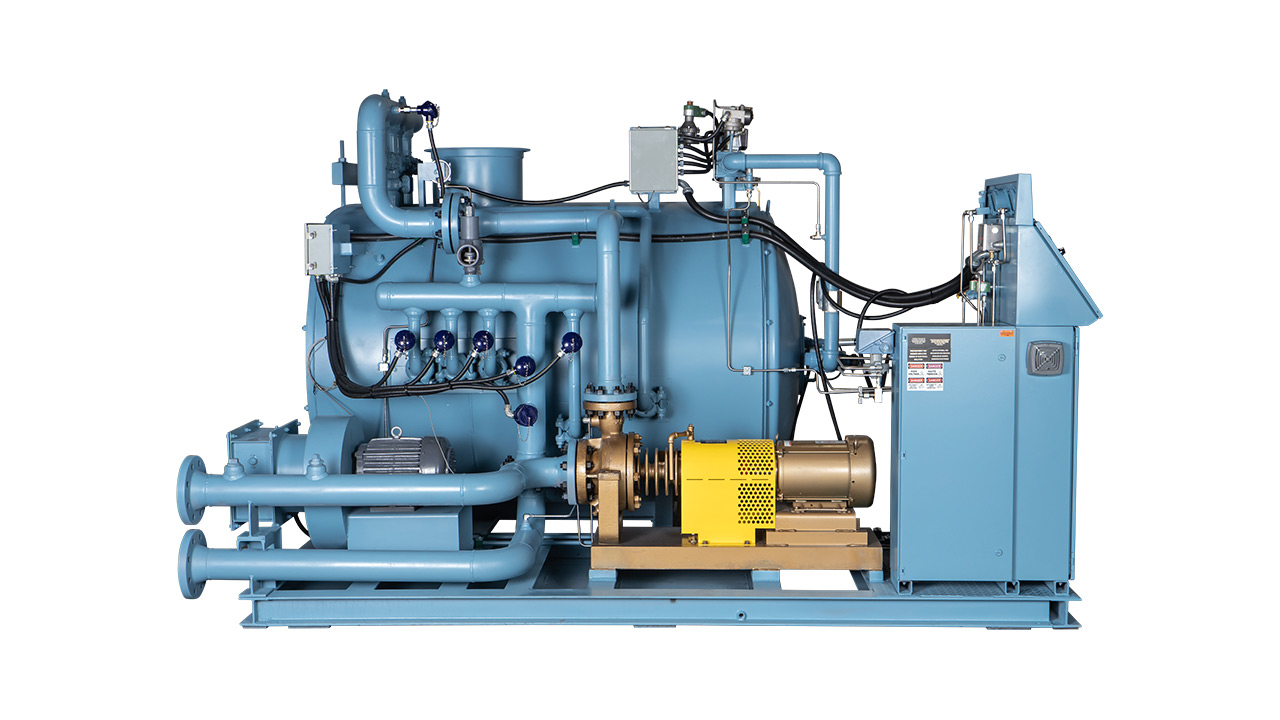

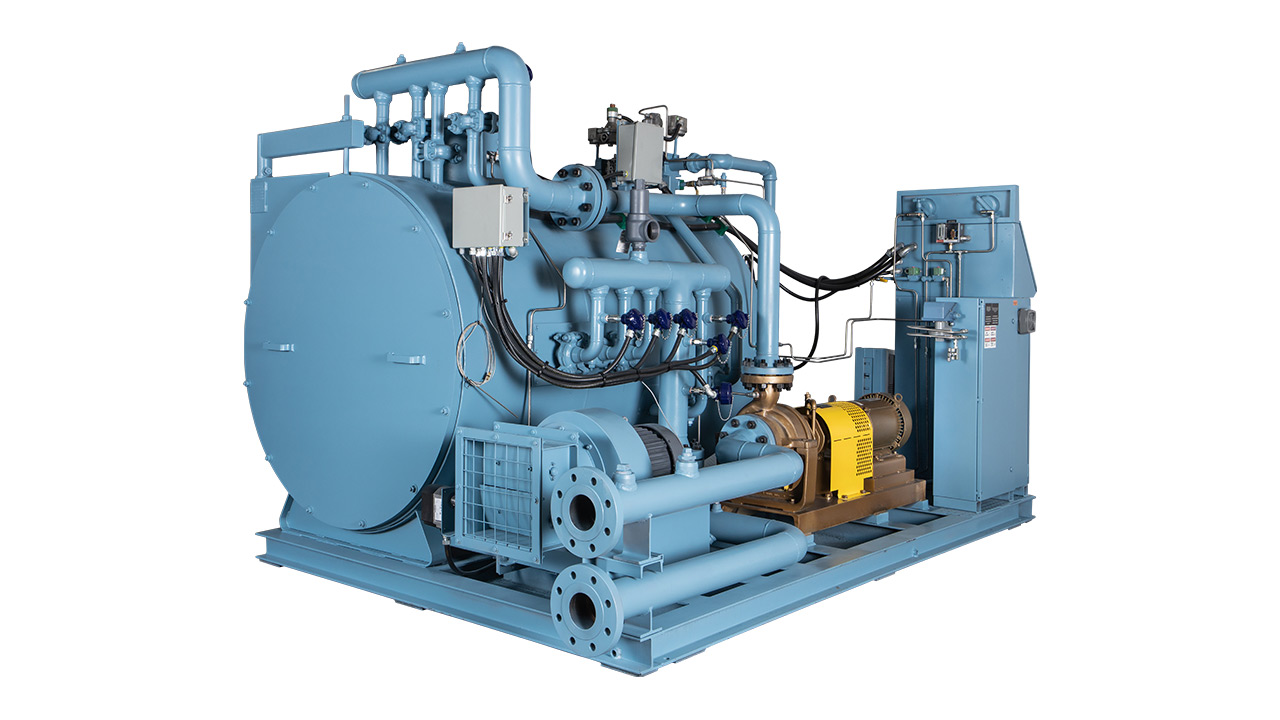

Forced Circulation, Multi-Coiled Tube, Forced Draft Fired.

Up to 84%.

Multi-orificed by Thermogenics.

Air Atomized by Thermogenics.

Air Atomized Oil, Multi-orificed Gas by Thermogenics.

Electric Spark Ignited, Interrupted Gas Pilot.

Up to 10:1 turndown.

Registered to ASME and CSA requirements and Hydro approved.

Programmed Flame Safeguard Control with Ultra Violet Flame Detection. Individual Coil Temperature Control and Outlet Temperature Limits.

750ºF design temperature, up to 250 PSIG.