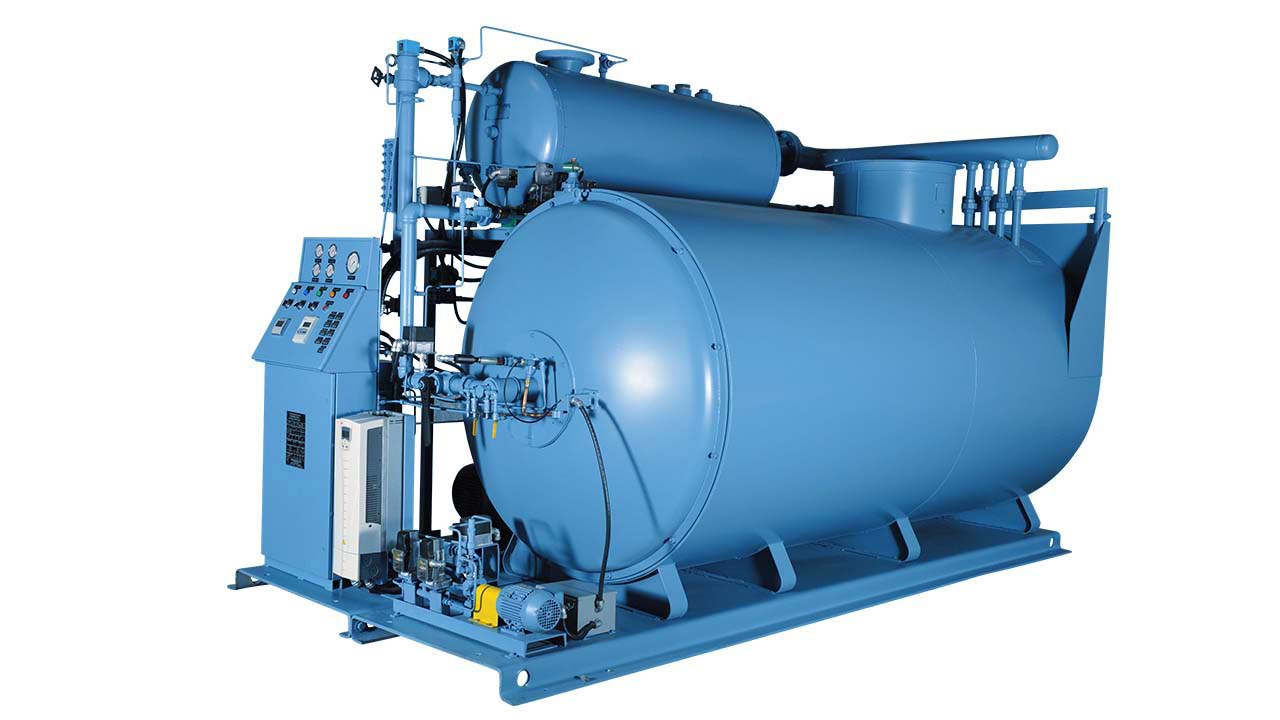

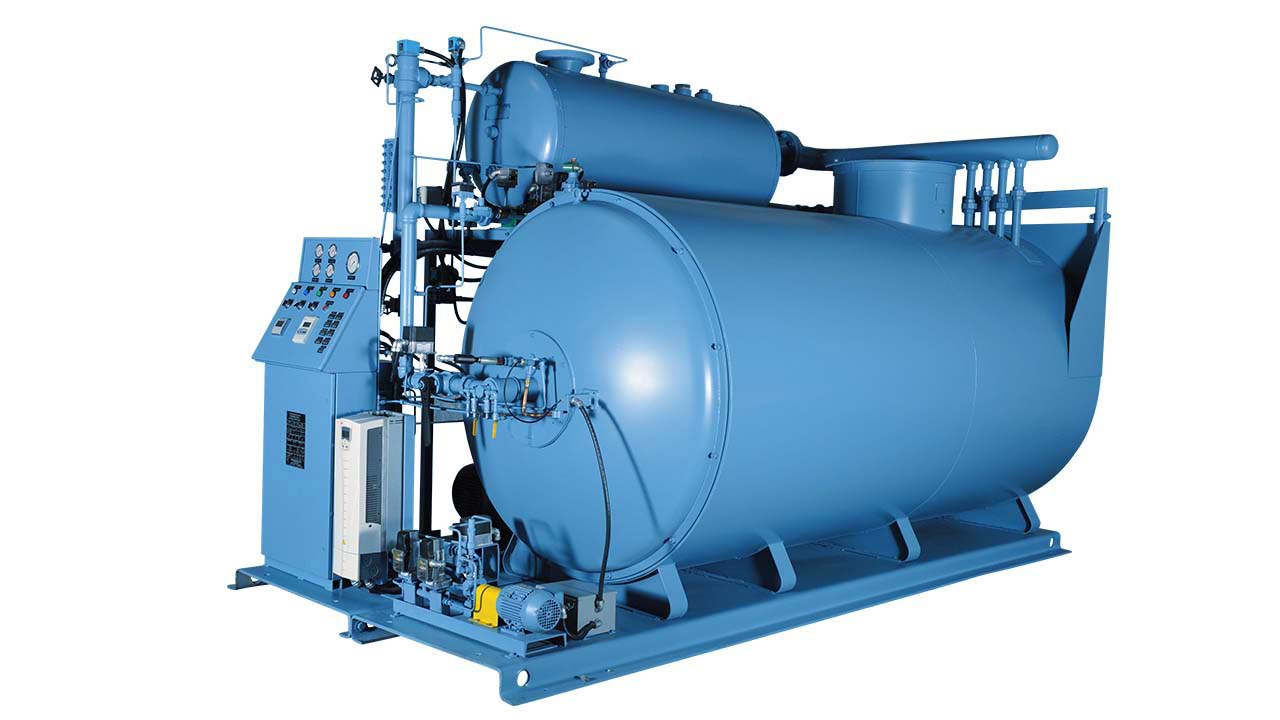

75 BHP to 600 BHP Output.

Standard 15 PSIG to 300 PSIG (higher on request).

Natural gas, propane and Number 2 oil.

Up to 85% efficiency with economizers.

ASME, NATIONAL BOARD or as specified. Complies with local code requirements as applicable.

Compliance with current noise and emissions regulations.

Packaged Deaerators

Therm-O-Pac Packaged Deaerators produce water with oxygen content less than .005cc per litre. Engineered with...

Learn MoreThermiser Heat Recovery

Preheat or process water from waste heat, three to seven percent average fuel savings...

Learn More